Choosing the correct oil for your air compressor is crucial for ensuring optimal performance. The type of oil you use can have major implications for your compressor’s efficiency, maintenance needs, and overall lifespan. At Pneumatic Engineering, we offer a variety of compressor oils and expert advice to help you make the best choice for your equipment.

Importance of Selecting the Right Compressor Oil

The oil used in an air compressor has multiple purposes, including lubrication, cooling, and sealing. Proper lubrication reduces friction between moving parts, preventing wear and tear. Cooling is essential to dissipate the heat generated during compression, while sealing helps maintain the desired pressure within the compressor.

Types of Compressor Oils

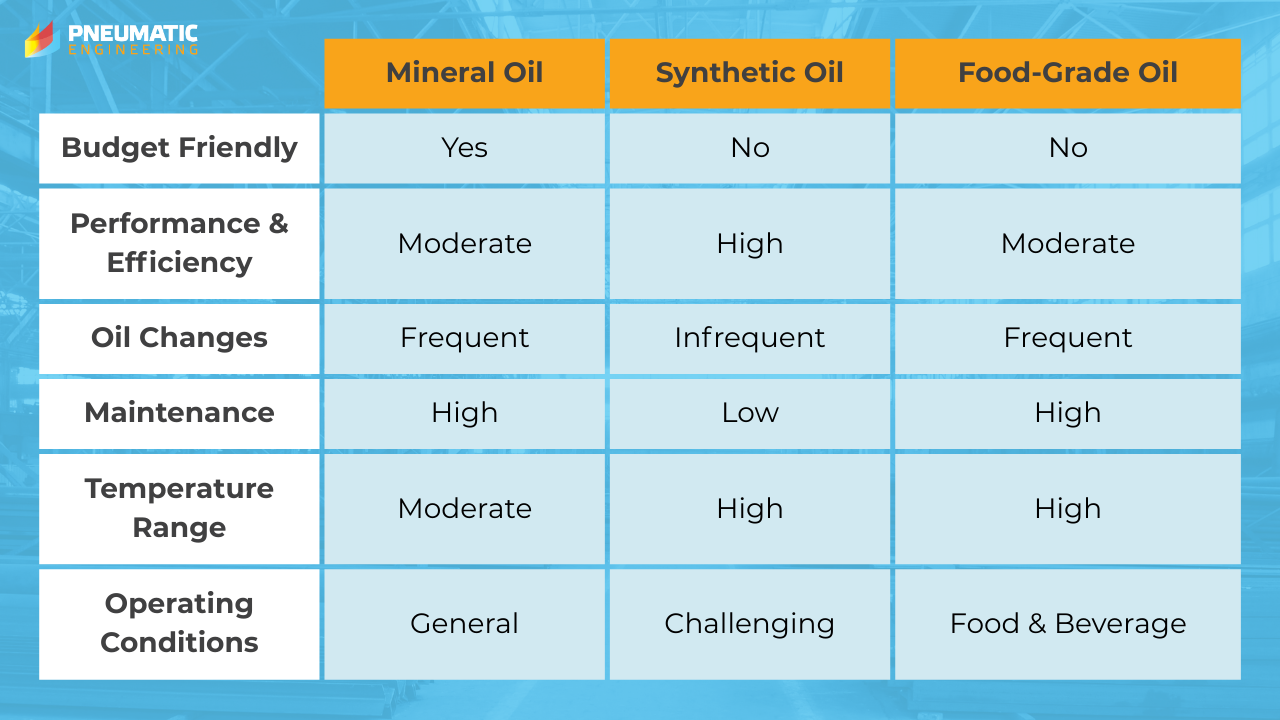

Compressor oils come in various types, each suited for different applications and operating conditions. The main types include synthetic oils, mineral oils, and food-grade oils.

Mineral Compressor Oil

Mineral oils, including ELGi Airlube XD mineral oil and ELGi Recip Lube Compressor Oil, are derived from refined crude oil. They are cost-effective and provide reliable performance for general compressor operations. Mineral oils are widely available and generally compatible with most compressor applications. However, using mineral oils compared to synthetic oils may require more frequent oil changes and increased maintenance, as they degrade quicker and may leave deposits in the compressor.

Mineral Compressor Oil is Best For: General-purpose applications and moderate environmental operating conditions.

Synthetic Compressor Oil

Synthetic oils, such as PES6000 and ELGi Airlube UT synthetic, are engineered for high performance and durability. These oils provide enhanced lubrication, reducing friction and wear on compressor components, which extends the lifecycle of your compressor. As they are longer-lasting and less likely to leave deposits or oxidise, fewer oil changes and less maintenance is required compared to mineral oils. Further, they offer excellent thermal stability, maintaining performance at high temperatures and reducing the risk of overheating, and excel in industries such as mining or in West Australia challenging remote environments.

However, synthetic oils are generally more expensive than mineral oils but are designed to keep your compressor running efficiently, providing optimal performance and minimising downtime. It’s also necessary to check the OEM recommendation as these oils may not be suitable for all types of compressors.

Synthetic Compressor Oil is Best For: Challenging environments or high demand applications where downtime is costly and can significantly impact operations.

Food-Grade Compressor Oil

Food-grade oils, such as Elgi Airlube FG Food Grade Oil, are specially formulated for compressors used in food processing and packaging. These oils meet stringent safety standards to prevent contamination and ensure compliance with food safety regulations. Food-grade oils provide high performance while ensuring that no harmful substances come into contact with food products.

Food-Grade Compressor Oil is Best For: Food and Beverage processing and packaging applications.

Choosing the Best Oil for Your Compressor Needs

The right oil for your air compressor depends on several factors, including your costs, operating conditions, and specific compressor requirements. Here’s a quick guide:

Understanding Compressor Oil Viscosity

Viscosity refers to the oil’s thickness and its resistance to flow and shear due to gravity. The viscosity index measures the oil’s viscosity in relation to temperature variations. High viscosity oils perform better at higher temperatures than low viscosity oils.

Key Considerations When Choosing Compressor Oil

You need to consider the compatibility with your compressor, application and operating environment!

Always refer to the OEM instructions to ensure the oil is compatible with the parts of your compressor. Factors such as the application, operating temperature, and environment can also influence the compatibility and impact the oil’s performance. Therefore, it’s recommended to consult with a specialist to ensure you are using the correct oil for your specific compressor model and application. This can help prevent potential issues such as breakdown and corrosion, which could be expensive to rectify in the future, and optimise the compressor’s efficiency and lifespan.

At Pneumatic Engineering, we specialise in providing high-quality compressor oils and expert advice to ensure your equipment runs efficiently. Our range includes mineral, synthetic, and food-grade oils to suit various applications and environments. Trust us to help you optimise your compressor’s performance and longevity.

Get in touch with us.

📞 Call us on (08) 6350 4802.