When it comes to the food and beverage manufacturing industry we appreciate the critical need for high performance machines that produce pure, contamination free air.

In food and beverage manufacturing, compressed air can directly impact product quality, hygiene, and output. If air that is used for conveying, filling, capping, packaging, or cleaning contains water, oil aerosols, particles, or microbes, it can create contamination risk and unplanned downtime. Australian food safety requirements emphasise protecting food from contamination, which can include matter carried by air.

Pneumatic Engineering supports food & beverage manufacturers in Western Australia, helping sites maintain compliant, reliable compressed air for production lines across dairy, meat processing, breweries, and packaging operations. We’ll help you match the right air compressor for the food industry to your duty cycle, then back it with servicing, air quality verification, and rapid response support.

Compressed air in the food industry is used across day-to-day plant operations, including

Because these touchpoints can sit close to product or primary packaging, the focus isn’t just “having enough air” — it’s having the right air quality class, stable pressure, and dependable uptime.

Food production doesn’t stop for equipment issues. Our team provides planned servicing and fast-response breakdown support to minimise downtime and protect throughput.

We troubleshoot pressure loss, high condensate carryover, filtration problems, control faults, and air quality issues that can lead to rejects or line stoppages.

A frequent question is: Can air contaminate food? Yes — if compressed air is not correctly treated and maintained, it can introduce particles, moisture, oil aerosols, and microorganisms that may contact product or packaging.

Under Standard 3.2.3 of the Food Standards Code, food premises and equipment must be designed to minimise contamination risks. The legislation places responsibility on the manufacturer to demonstrate that contamination risks are controlled. This is where defined compressed air quality standards and documented testing become critical.

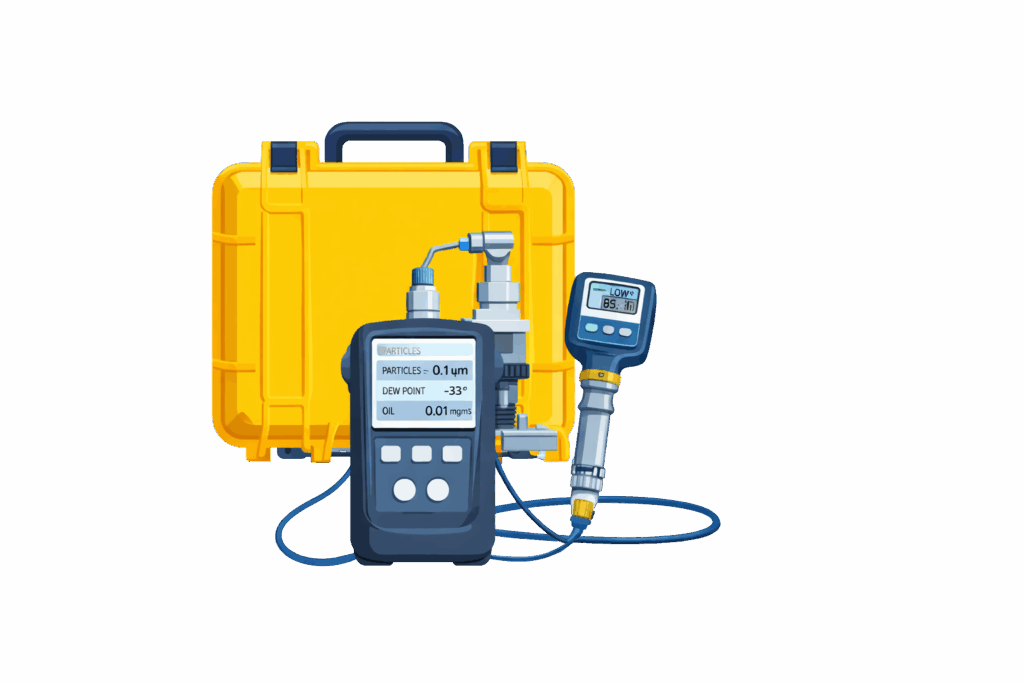

Many manufacturers use ISO 8573-1 as the reference framework to define and verify compressed air purity classes (particles, water, and oil).

For higher-risk points of use (direct or indirect contact with product/primary packaging), sites often specify Class 0 oil-free compressor solutions and high-performance filtration/drying, then validate outcomes through testing.

If your process demands the lowest contamination risk, we can support Class 0 oil-free compressors, hygienic system design, and high-quality filters suited to your required ISO class. This approach supports HACCP-style risk controls by reducing contamination pathways and ensuring your compressed air quality is demonstrably fit-for-purpose.

Oil-free compressors are not the only compliant solution. Many food manufacturing sites operate oil-lubricated compressors successfully, provided they are correctly designed and maintained.

Where oil-lubricated compressors are used in food production environments, food-grade compressor lubricants should be considered. These oils are typically NSF H1 registered, meaning they are suitable for incidental contact with food in accordance with recognised food safety guidelines.

A food & beverage compressor solution is only as good as the system around it. We design complete systems — compressor, dryers, filtration, condensate management, pipework, point-of-use treatment, and controls — to deliver stable pressure and repeatable air quality at the application.

If you need confidence that your compressed air is meeting your internal requirements (or customer audit expectations), we provide compressed air quality testing aligned to ISO 8573-1 measurement principles, with reporting that helps you set corrective actions and maintenance intervals.

If you’re facing a breakdown, peak demand, or a planned shutdown, we offer rental compressors and air solutions to keep production running while repairs or upgrades are completed. We can also provide temporary air treatment configurations to suit higher-risk applications where air purity is critical.

Pressure equipment compliance still matters in food and beverage plants. We support inspection and registration requirements for applicable plant to help you stay audit-ready and reduce operational risk. Generally, air receivers should be inspected every two years at least.

If you’re a WA manufacturer and you need a reliable air compressor for the food industry, talk to Pneumatic Engineering. We’ll help you select the right compressor type, design a compliant compressed air system, verify air quality, and keep the site running with servicing and 24/7 support.

When it comes to food-grade compressors in WA, we are the experts.

Contact us today to discuss your application, air quality requirements, and whether oil-free or additional filtration is the right fit for your process.