Compressed air is often referred to as the fourth utility in food manufacturing. It is used in processing, conveying, packaging, cleaning, and control systems across food and beverage facilities. Despite how common it is, compressed air is also a potential source of contamination if it is not properly designed, filtered, and maintained.

For food manufacturers in Western Australia, understanding air quality standards is critical for meeting legal obligations, maintaining food safety, and passing audits. This article explains what is required by law, what is considered best practice, how ISO 8573-1 applies to food production, and how air quality compliance affects your compressed air system.

Food Standards Code requirements for compressed air

Under Standard 3.2.3 – Food Premises and Equipment of the Australian Food Standards Code, administered by Food Standards Australia New Zealand, food businesses must ensure that equipment is designed and constructed to minimise contamination risks. This includes contamination from airborne sources that could compromise food safety or suitability.

Compressed air that comes into direct or indirect contact with food, food contact surfaces, or packaging is therefore considered part of the food safety risk profile. While the standard does not prescribe a specific compressed air quality class, it places a clear obligation on food manufacturers to control contamination risks associated with utilities such as compressed air.

Food safety programs and air quality control in compressed air systems

Most food and beverage facilities operate under a documented food safety program. These programs are required to systematically identify hazards, determine control measures, monitor those controls, and keep records demonstrating compliance.

From a compressed air perspective, this typically means identifying risks such as oil carryover, moisture, particulates, microorganisms, and odours. Controls may include appropriate compressor selection, filtration, drying, routine servicing, and air quality testing. Regular review of the food safety program should confirm that compressed air controls remain effective as production changes or equipment ages.

ISO 8573-1 and compressed air quality classes

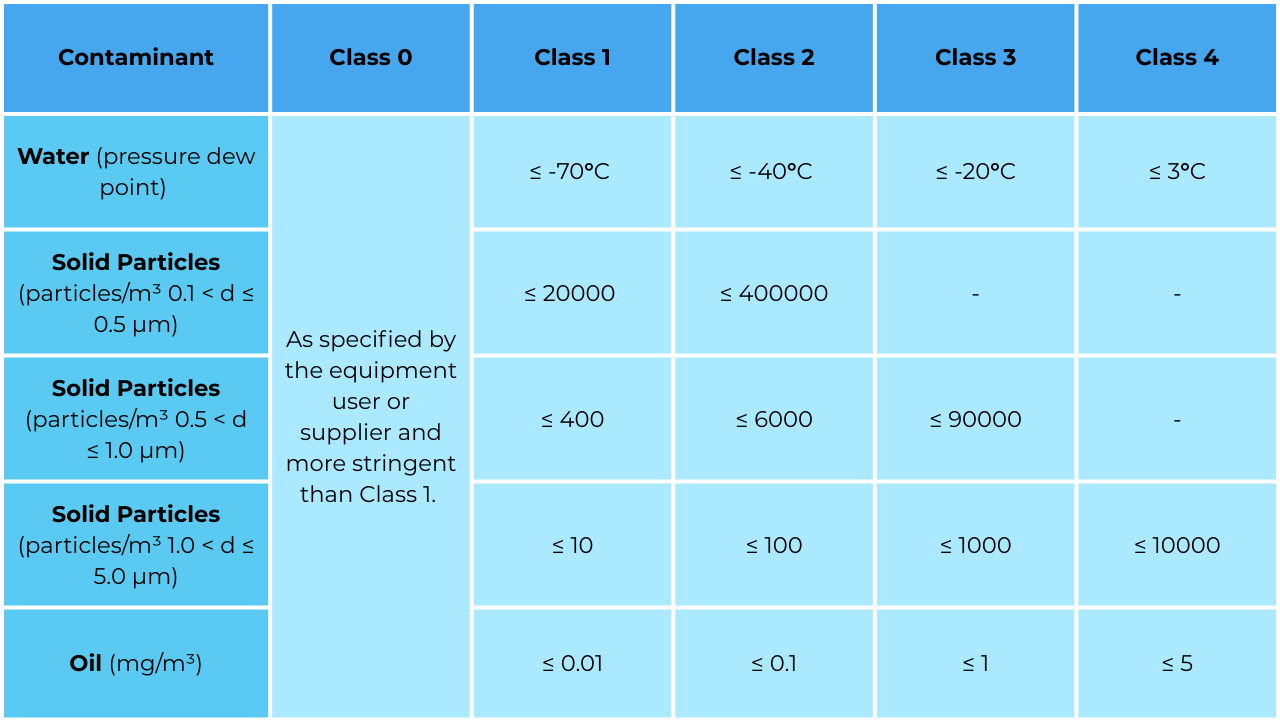

ISO 8573-1:2010 (to be replaced by ISO/AWI 8573-1) is the internationally recognised standard for classifying compressed air quality in food manufacturing . It defines air quality classes based on three main contaminants: solid particles, water, and oil. Each is assigned a class number, with lower numbers representing cleaner air.

In food manufacturing, ISO 8573-1 is widely used as a benchmark for defining acceptable compressed air quality, particularly where air comes into contact with products or packaging. Many businesses reference an ISO 8573-1 air quality chart within their quality assurance documentation to clearly define required air classes at different points of use.

Best practice is to specify the required ISO 8573-1 class based on risk, rather than applying a single standard across the entire site. For example, compressed air used for direct product contact will require a significantly higher air quality than air used for non-contact pneumatic tools.

HACCP and private certifications for compressed air in food manufacturing

Hazard Analysis and Critical Control Points (HACCP) frameworks rely on identifying and controlling risks throughout the food manufacturing production process. Compressed air is often included as a potential hazard, particularly in packaging, conveying, and product handling.

In addition to HACCP, many food manufacturers are audited against private or retailer-driven certification schemes. These certifications commonly require evidence that compressed air quality is controlled, monitored, and verified. ISO 8573-1 is frequently referenced during audits as the accepted technical standard for compressed air quality.

This is where working with suppliers of HACCP-compliant air compressors and filtration systems becomes critical, particularly for facilities seeking to strengthen their quality assurance and quality control processes.

How air quality compliance affects compressed air systems

Meeting air quality standards has direct implications for how compressed air systems are designed and operated. System servicing becomes more critical, as poorly maintained compressors, dryers, and filters can quickly compromise air quality. Preventative maintenance and documented service records are often reviewed during food safety audits.

Product choice also plays a key role. Oil-free compressors are commonly selected for food production areas to reduce contamination risk and simplify compliance, particularly in high-risk applications. However, oil-lubricated compressors can still be suitable when paired with correctly designed filtration and monitoring systems.

Read more: Oil-Free vs Oil-Lubricated Compressors: What Food Manufacturers Need to Know

Air quality testing is another essential component. Routine testing against ISO 8573-1 provides objective evidence that the system is performing as intended. Test results support audit readiness and help identify emerging issues before they affect production or product safety.

Compressed air quality is a critical but often overlooked component of food safety. While Australian regulations focus on outcomes rather than prescriptive limits, standards such as ISO 8573-1 provide a clear framework for defining, measuring, and maintaining safe compressed air. For food manufacturers in WA, aligning compressed air systems with food safety programs, HACCP principles, and recognised air quality standards is essential for compliance, quality assurance, and operational confidence.

Compressed air quality checklist for food manufacturers

- Identify where compressed air contacts food, packaging, or food contact surfaces

- Define required ISO 8573-1 air quality classes for each application

- Select appropriate air compressors, dryers, and filtration systems

- Implement routine servicing and maintenance schedules

- Conduct regular air quality testing and retain records

- Review compressed air controls as part of your food safety program

- Engage suppliers experienced in food industry air compressors and compliance

If you operate a food or beverage facility in Western Australia and are unsure whether your compressed air system meets current food safety and air quality standards, speak with a compressed air specialist. An assessment, air quality test, or system review can help ensure compliance with ISO 8573-1, support HACCP requirements, and keep your operation audit-ready.